FREE Toolbox Talks

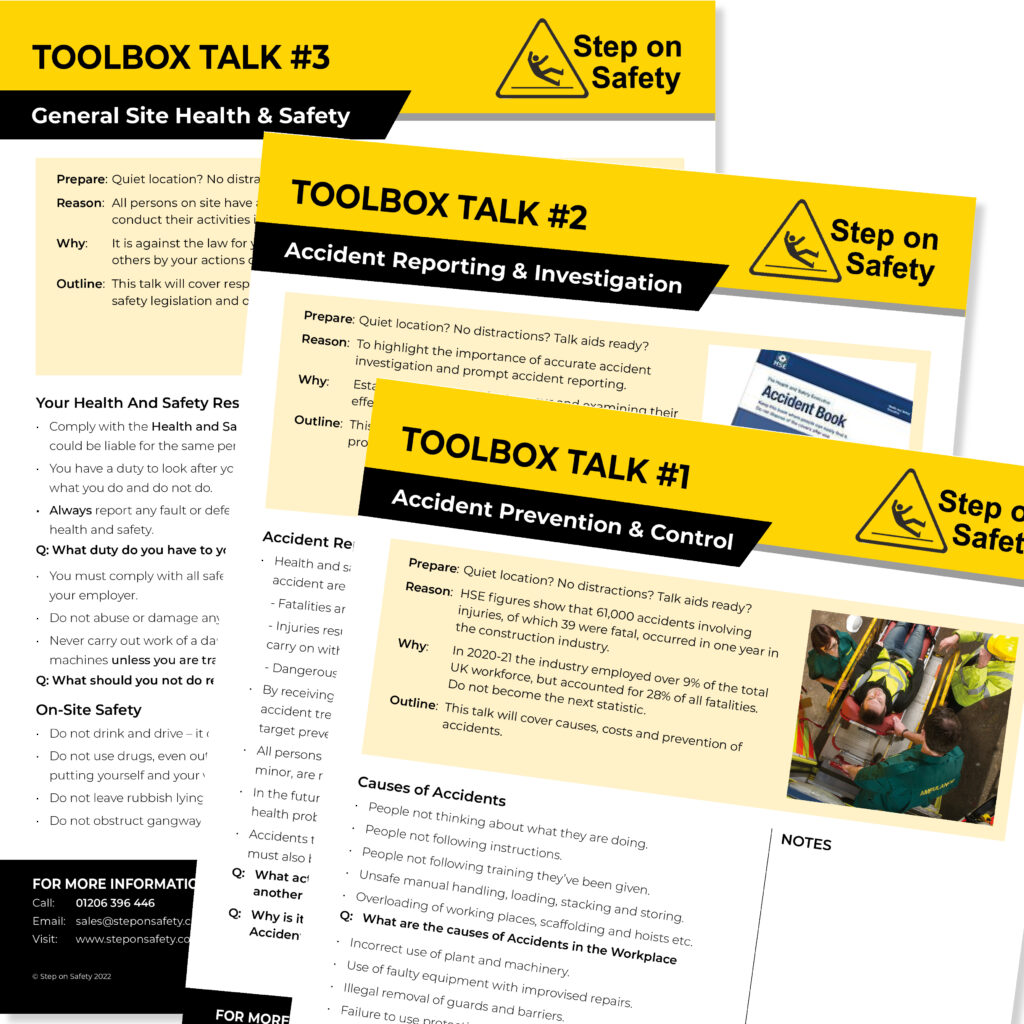

Welcome to Step on Safety’s Toolbox Talks – a series of FREE, downloadable discussion guides to help you ensure your site teams have the knowledge and information they need to stay as safe as possible while at work.

What is a Toolbox Talk?

Designed to be short and and to the point, a Toolbox Talk is a presentation to the workforce on a single aspect of health and safety. They can be in whichever format suits you best – video, PowerPoint or a simple PDF – Step on Safety’s versions are downloadable PDFs. Each one will have space for you add your own notes and questions to ensure it is kept relevant to the team or the site you are working with. They should only take 15 to 20 minutes each so can easily be added into regular team meetings or Safety Briefings.

How to give a Toolbox Talk

There is no one-size-fits-all approach, adapt your talk to suit the people attending; those for whom English is a second language may need you to explain things differently, new team members may need more explanation, while old hands might be impatient to leave. As long as you get the points across you can consider it successful. Take a look at HSE’s helpful guide to running a successful Toolbox Talk for more advice.

- Explain why you are having a toolbox talk in a way that will help your workers relate to the topic you want to cover.

- Use our PDFs as guides, but try to keep the presentation informal, conversational and easy to digest. The HSE website also has a number of free materials including downloads.

- Make sure you’re in an environment that is conducive to learning – where you won’t get interrupted or distracted

- Prepare what you are going to talk about and any materials that you are going to use. Where relevant, use visual examples and real equipment, to relay the information

- Ensure you understand the subject yourself and encourage workers to participate by asking them questions about the topic.

- Do a wrap-up at the end of the talk to reinforce important points. And make a note of who attended so you can run catch-up sessions for individuals that weren’t there.

- It’s important to get feedback on the impact, messaging and content of the toolbox talk. Ask workers what they thought about it and consider asking another supervisor or manager to observe one of your talks. Make a note of any suggestions to apply next time you present – the same subject or a new one

It only takes one

There are – on average – 60,000 work-related accidents on UK construction sites EVERY YEAR. If, by taking the time to train your teams, you prevent one accident, then your Toolbox Talks will have been time well spent.

#1 Accident Prevention & Control

#2 Accident Reporting & Investigation

#3 General Site Health & Safety

#4 Safe Working at Height

#5 Hand-held Power Tools

#6 Electricity on Site

#7 Manual Handling

#8 Alcohol & Drugs on Site

#9 Sun Safety

#10 Abrasive Wheels

#11 Pollution Control

#12 PPE

#13 Fire Prevention

#14 Vibration

#15 Security on Site

#16 Asbestos

#17 Safety Inspections

#18 Protection of Eyes

#19 System Scaffold

#20 Young People on Site

#21 Safety with Steelwork

#22 Waste Management

#23 Health on Site

#24 Lead Hazards

#25 COSHH

#26 First Aid

#27 Signallers & Slingers

#28 Hard Hats

#29 Working Over Water

#30 Plant Equipment

#31 Mobile Plant

#32 Safe Stacking of Materials

#34 Protection of Skin

#35 Lifting Accessories

#36 Trestles & Stepladders

#37 Vehicle Fuels

#38 Lifting Equipment

#39 Ladders

We are also the only accredited supplier of specialist NVQ courses on working with GRP and now offer an accredited CPD seminar on Riser Floors. If you’d like to find out more please get in touch.