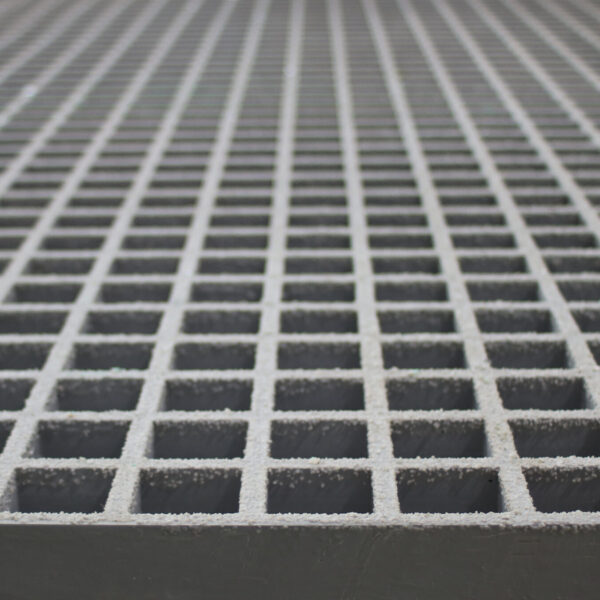

GRP Installation Services

At Step On Safety, we pride ourselves on delivering top-quality GRP (Glass Reinforced Plastic) installation services. Our directly employed teams of experts receive extensive training to work effectively with GRP materials and are committed to providing exceptional service. They are certified to operate in a wide range of industrial environments and undertake additional training when required for specific sites.

Site Qualifications

All our installation staff are fully trained in the following areas:

- Abrasive Wheels

- Asbestos Awareness

- Face Fit

- Harness and Lanyards

- Ladders and Steps

- Manual Handling

- PASMA (Prefabricated Access Suppliers’ and Manufacturers’ Association)

- Working at Height

In addition, our Site Supervisors hold the following qualifications:

- First Aid

- IPAF (International Powered Access Federation)

- SSSTS (Site Supervisors’ Safety Training Scheme)

For certain installations, we obtain specific job-dependent certifications, including:

- Banksman

- Confined Spaces

- Water Hygiene Card – English (EUSR) and Scottish (DOMS)

We ensure that all new team members meet the high standards set by our experienced crews through comprehensive in-house training. We are proud to be the only NVQ Accredited company that provides this level of training.

What to Expect from Our Installation Services

While there are variations depending on the size and scope of the installation, we follow a consistent methodology for every project:

- Site Visit: A site supervisor will assess access, delivery points, and available space. Recommendations will be shared with the office teams during a pre-start meeting to ensure the installation team is fully prepared.

- Area Preparation: On the first day, the installation team will arrive, set up tools, and cordon off the work area to avoid accidents. They will also meet with the site manager to go over important details such as fire exits, waste disposal, and the best spots for refreshments.

- Materials Delivery: The team will unload the materials or fabrications needed for the installation.

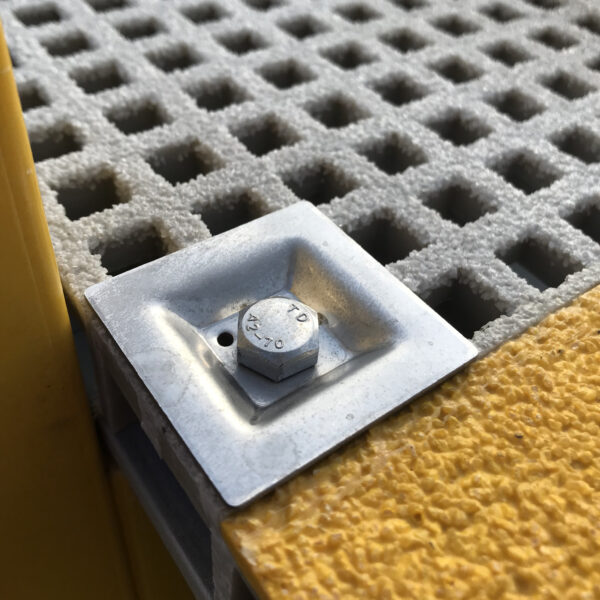

- Setting Out: Materials and fixings will be gathered and checked to ensure everything is ready for installation.

- Installation: The team will proceed with the installation according to the agreed program, keeping the site manager informed of their progress. They will clean and tidy the work area at the end of each day.

- Quality Checks/Walkouts: Once the installation is complete, the client will have the opportunity to inspect the work to ensure it meets their expectations.

- Snagging: Any issues identified during the quality checks will be addressed, and a follow-up inspection will be arranged.

- Testing, Commissioning & Handover: Once the client is fully satisfied with the installation, the team will pack up, clear the site, and provide any necessary documentation and signage.

Our goal is to ensure that every client is completely satisfied with the installation services they receive.

Find out more

Let our experts install your GRP for you

Mon-Fri 8:30am to 4:30pm