Pumping Station Chamber Renovation

A chance encounter a couple of years ago has resulted in the development of a close, collaborative relationship between Step on Safety and client Anglian Water, clearly demonstrated by the recent refurbishment project at the London Road Pumping Station in West Thurrock.

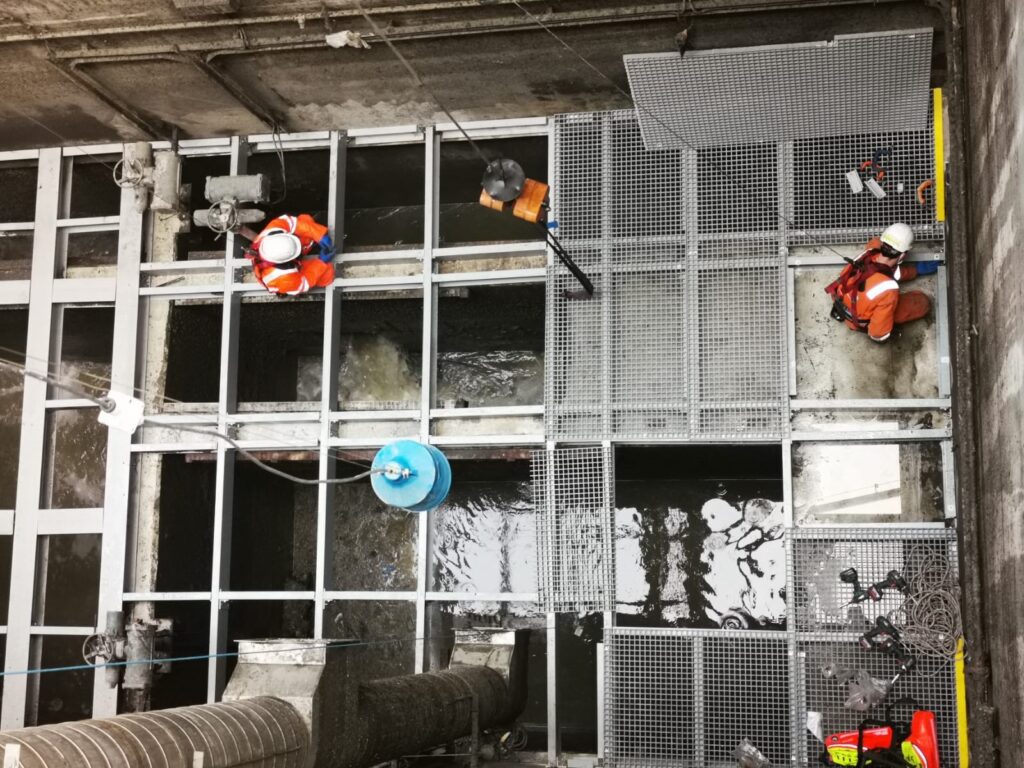

The station has four large foul chambers, each with maintenance platforms up to 11 metres deep providing access to the inlet and outlet pumps. The existing steel grating and handrails had begun to corrode, rendering at least one of the chambers unsafe to enter. An urgent solution was required to replace some or all of the platforms in each one – a challenge under any circumstances but even more so in working chambers during flood season.

The first issue was access. The chambers are classed as Level 3 Enclosed Spaces so can only be entered by qualified engineers. The condition of the platforms was, in some cases, so poor that the surveys had to be done using 3D scanners lowered into each pit. The uneven build-up of residue on the walls and existing surfaces resulted in imprecise measurements which meant that whatever material was used, some adjustment would be necessary once work started. GRP was the ideal choice because it’s faster and easier to cut – even when you’re working in a hole. It’s also lighter so easier to manoeuvre into position.

The second issue was the installation itself. Because of the access restrictions, Step on Safety teams were unable to go down into the chambers to install it themselves; specialist Anglian Water engineers completed the install whilst working collaboratively with Step on Safety onsite service teams cutting, bonding and fabricating up top. It was agreed that an SoS installer would be onsite throughout the project, assisting and advising the AW teams every step of the way.

The new platforms were built just above the old steel ones, which acted as a safety net during the installation. Most of the cutting and assembly was done at the SoS workshop Brantham, Suffolk, with only minor adjustments needed during the project. The GRP profiles, open mesh grating and handrail was all made using isophthalic resin which has superior resistance to the toxic environment it will sit in. As an added precaution, every cut edge was treated with resin to maintain the integrity of the materials. Once the GRP was in place, the rotten steel was disassembled and lifted out for disposal.

Step on Safety’s Dave Atkins worked alongside Anglian Water crews to get the project done. “It was a new way of working for us as we are usually down in the working areas hands-on” he told us. “Communication from top side was critical in which and what measurements were needed for a smooth project installation. Marcin and Ken’s team were fantastic and I’m really happy with what we have achieved together.”

Clear, effective communication was key to the success of the project and Marcin Jacobowski was more than happy with the outcome. “I would like to take this opportunity to thank everyone for helping me to complete this project” he wrote. “We had a lot of problems during the project (flooding incidents), but we managed at the end. What have I learned is, without the good communication and co-operation with AW Operations and the subcontractors’ support (Cadman & Step on Safety) this scheme wouldn’t be the success that it is. I can highly recommend Step on Safety for quality of work and great communication.”

To find out more about replacing damaged, corroded steel in your environment, get in touch.

You can download this case study here