Description

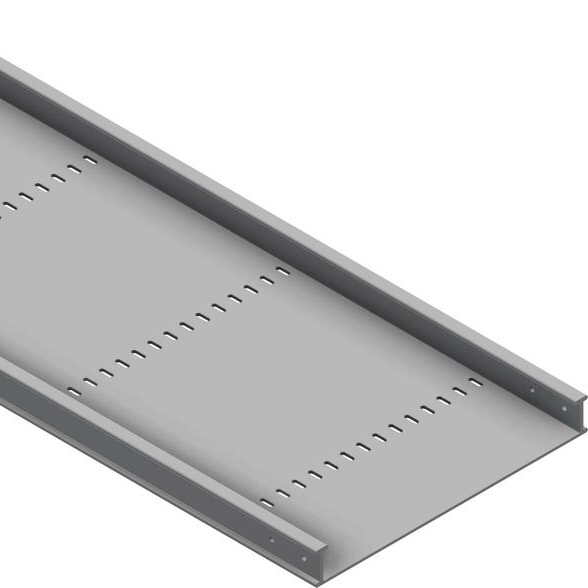

Keep cables tidy on site ensuring easy access and maintenance in the future. Our corrosion resistant GRP Cable Trays are lighter than metal equivalents while maintaining strength and maximising loading capability.

- Perforated tray design prevents water or chemicals from pooling inside the tray, reducing the risk of damage to the cables

- Lower weight and rounded edges makes tray easier to handle and reduces accidents on site

- Unique I-beam profile design increases load capacity and reduces deflection

- Made from non-conductive pultruded Glass Reinforced Plastic.

- Pre-drilled, full height splice connectors can handle the same loadings as the tray system itself

- Wide range of tray widths available – for a larger capacity system please see our GRP Cable Ladders

- Supplied in 3000mm lengths

Although not listed here, we can also source a complete system of covers, fixings and connectors – just ask for details.

Polyester is the most widely used resin system. It offers good weathering properties with resistance to ultraviolet light and has good corrosion resistance. Our Polyester resin has been specially formulated to meet certain fire and smoke standards and is classified as a “class 1” resin in accordance with BS476 P7 and ASTM E84. Our standard polyester resin product range is UL approved.

|

Cable Tray

|

Length |

Internal Width |

External Width |

Internal Height |

External Height |

Wall Thickness |

Weight |

SWL (2m) |

SWL (3m)

|

|

50mm

|

3000mm |

50mm |

70mm |

47mm |

50mm |

3mm |

3.9kg |

70kg/m |

59kg/m |

|

100mm

|

3000mm |

100mm |

122mm |

47mm |

50mm |

4mm |

5.3kg |

70kg/m |

59kg/m

|

|

150mm

|

3000mm |

150mm |

172mm |

47mm |

50mm |

4mm |

6.1kg |

70kg/m |

59kg/m

|

|

200mm

|

3000mm |

200mm |

222mm |

47mm |

50mm |

4mm |

7.0kg |

70kg/m |

59kg/m

|

|

300mm

|

3000mm |

300mm |

324mm |

47mm |

50mm |

5mm |

9.2kg |

70kg/m |

59kg/m

|

|

400mm

|

3000mm |

400mm |

424mm |

47mm |

50mm |

5mm |

13.6kg |

70kg/m |

59kg/m

|

|

600mm

|

3000mm |

600mm |

624mm |

47mm |

50mm |

5mm |

19.2kg |

70kg/m |

59kg/m

|

Loading data according to IEC61537. The length of the end span must be reduced to 3/4 of the support spacing and with no splices on the end span. *Tested without underside splice connector.